Start your career at Hannusch Industrieelektronik.

Together we can achieve a lot. We are here for you when you need us.

Comprehensive experience through extensive fields of activity in many technology and manufacturing areas. Constant dialogue with our customers forms the basis for a trusting and open partnership. Customer satisfaction, competent advice & support, and high service quality are the top priorities. Successfully addressing customer requirements and market challenges with flexible structures.

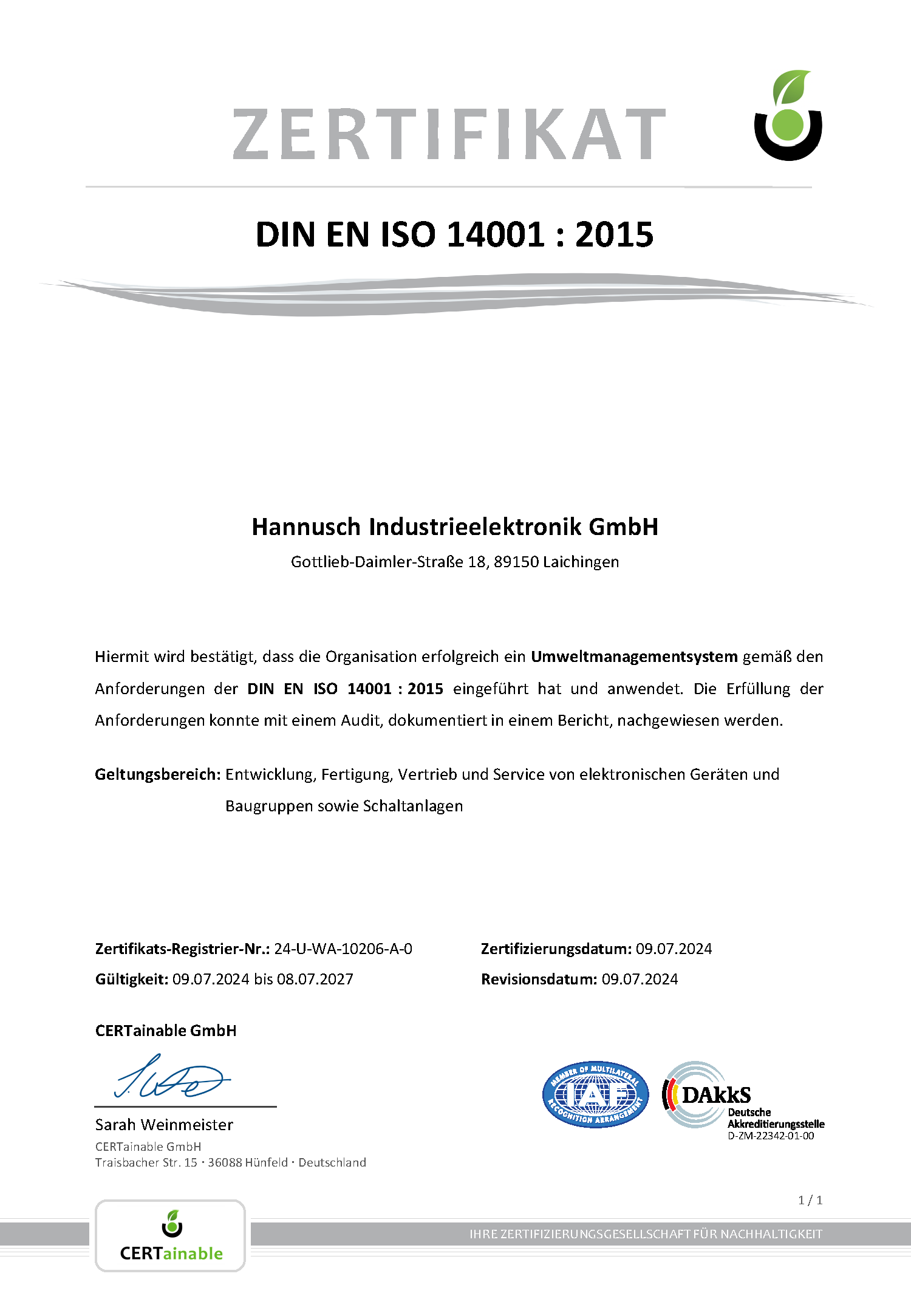

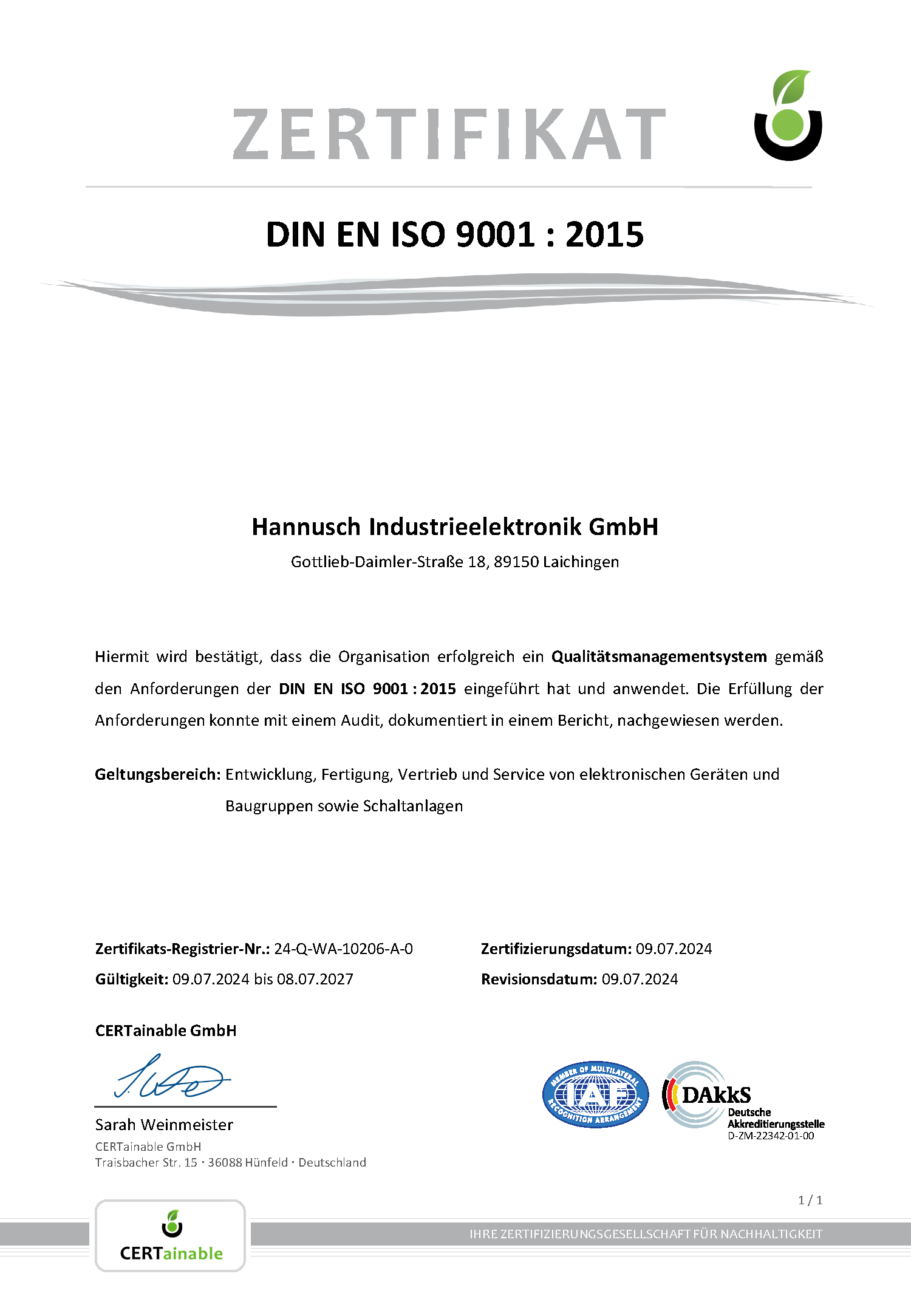

We are certified according to the QM standard “DIN EN ISO 9001” and “DIN EN ISO 14001”.

Comprehensive experience through our extensive fields of activity in the following areas.

Test setups, software installations, final test

We offer comprehensive solutions from the setup of individual test assemblies to the installation of required software and the final end test, ensuring the highest quality and functionality.

3 SMD placement lines with nitrogen reflow & vapor phase technology

Three state-of-the-art SMD placement lines with nitrogen reflow and vapor phase technology for precise and reliable manufacturing of electronic assemblies.

After Sales Service

Comprehensive support after delivery, including repair, maintenance, and technical advice.

Rework

Precise reworking and repair of electronic assemblies for the highest quality and durability.

Coating

Protection and refinement of electronic assemblies through precise coating processes.

Potting

Reliable protection of electronic components through high-quality potting for maximum security and durability.

Control Cabinet and Plant Construction

Planning, manufacturing, and assembly of control cabinet and plant systems offering maximum efficiency, safety, and reliability.

Complete Systems & Device Manufacturing

Development and manufacturing of individual complete systems and devices according to the highest quality standards.

Support

THT production line with nitrogen wave soldering system and 2 selective soldering systems

State-of-the-art THT production line with nitrogen wave soldering system and two selective soldering systems for precise and reliable solder connections.

AOI, AXI, ICT, individual functional test stands

Utilization of the latest testing methods such as AOI (Automated Optical Inspection), AXI (X-ray Inspection), and ICT (In-Circuit Test) as well as custom functional test stands to ensure the highest quality and functionality.

Prototype and Series Production, SMD and THT

Manufacturing of prototypes and series in SMD and THT technology to provide tailored solutions quickly and reliably.

Logistics and Packaging Management

Efficient planning and implementation of logistics processes as well as custom packaging solutions for safe transport and swift delivery.

Framework Contracts

Long-term agreements for continuous deliveries and services that offer flexibility and planning security.

Mechanical Components

Precisely manufactured mechanical parts and assemblies that meet the highest quality standards and are perfectly tailored to your needs.

Partial or Complete Assemblies

Individual assembly services, from partial assembly to complete final assembly, for tailored solutions and efficient production processes.

Cable Assembly

Individual manufacturing and customization of cables and wires according to specific requirements for optimal functionality and reliability.

Our Environmental Management more safety and quality for humans, animals, and nature.

Our Environmental Management more safety and quality for humans, animals, and nature.

A clean environment is the foundation for progress, health, and also quality of life. Environmental protection and resource conservation have been an essential part of our thinking and actions since the company’s inception.

We constantly focus on saving materials, water, and energy, as well as developing consumption optimization further.

A PV system also ensures CO2 avoidance of approximately 35 tons per year.

Hannusch strives to connect ecology and economy sensibly. We separate waste as far as sensible, in a sorted manner at the source, and bring it to recovery or proper disposal with minimal environmental impact.

We are committed to compliance with relevant environmental laws and regulations. Our environmental management and awareness are supported by the competent and responsible actions of our employees.

Since 2005, Hannusch has also been certified according to “DIN-ISO 14001”.

A clean environment is the foundation for progress, health, and quality of life. Environmental protection and resource conservation have been essential parts of our thinking and actions since the company’s founding.

We are constantly mindful of saving material, water, and energy, as well as further developing consumption optimization.

A PV system also ensures CO2 avoidance of about 35 tons per year.

Hannusch strives to sensibly combine ecology and economy. We separate waste, where sensible, by type at the place of origin, and direct it to recycling or proper disposal with minimal environmental impact.

We commit to complying with relevant environmental laws and regulations. Our environmental management and awareness are sustained by the competent and responsible actions of our employees.

Since 2005, Hannusch has also been certified according to “DIN-ISO 14001”.

Timeline of Hannusch Industrieelektronik.

Foundation

Gründung Hannusch Industrieelektronik in Ringingen

First move to Berghülen

Second move to Blaubeuren

Third move to Laichingen

Fourth move

Umzug ins heutige, firmeneigene Gebäude nach Laichingen - 10 Jahre Hannusch Industrieelektronik

Handover

Firmenübergabe von Herrn Hans-Peter Hannusch an Frau Claudia Hannusch

15 years of Hannusch Industrieelektronik

Frauenhofe Institute

Beginn der Teilnahme an verschiedenen Projekten mit den Fraunhofer Institut ISIT in Itzehoe, bis heute

Planning and construction start

„Erweiterungsbau 1“ - 1000 qm zusätzliche Produktions- und Lagerfläche

Completion and move

in „Erweiterungsbau 1“

20 years

Hannusch Industrieelektronik, mit Feierlichkeiten und Technologietag

Foundation

Gründung der Tochterunternehmen Hannusch Schulung & Technologie Hannusch ESD Equipment

Planning and construction

(mehrere Ausbau-Varianten, max. 5 Stockwerke, gesamte Fläche: 6000 qm)

Anniversary

25 Jahre Hannusch Industrieelektronik

Expansion building 2

„Erweiterungsbau2“ 2.000 qm zusätzliche Produktionsfläche und 500 qm zusätzliche Bürofläche

Training center

Eröffnung unseres neuen Schulungscenter mit 300 qm Fläche.

E2MS Award

E2MS-Award 2015 Gewinner im Bereich Firmenkultur (Verliehen durch den FED)

Anniversary

30 Jahre Hannusch Industrieelektronik

Solar system

Installation und Inbetriebnahme Solaranlage 99,8 kW

Rebranding

Umfirmierung in die Hannusch Industrieelektronik GmbH, Geschäftsführer Claudia Hannusch und Michael Hannusch

Anniversary

35 Jahre Hannusch Industrieelektronik